In actual projects, besides using wire-wound resistors, various types of resistors such as metal film resistors, metal oxide film resistors, and carbon film resistors may be used in more scenarios. Since wire-wound resistors can already be achieved through wire winding, why do we need so many different types of resistors?

This is because resistors produced by different processes and principles have different resistance values, volumes, costs, accuracies, power ratings, high-frequency characteristics, and noise characteristics. When different characteristics are required, resistors produced by different manufacturing methods are needed, thus resulting in the need for various types of resistors to meet the demands of different scenarios.

Factors aligned with different types of resistors:

1. Resistance Value and Volume

Although different lengths of wire can achieve different desired resistance values, due to the relatively small resistance of metal wire, different resistance ranges should be achieved through different material processes. At the same time, in many scenarios, the volume of resistors cannot be particularly large. Therefore, material processes that can achieve small volume and high resistance values have significant advantages.

2. Cost

Different materials have different costs, and different manufacturing processes will also result in different costs. Assuming the production material costs are the same, the larger the shipment volume, the lower the cost. More importantly, the total usage of the material in society will also lead to different costs.

3. Accuracy

The main differences between high-precision resistors and ordinary resistors are the size of resistance value error and temperature coefficient. The classification is described as follows: For resistors with a resistance value above 1Ω, resistors with a resistance value error within ±0.5% compared to the marked resistance value can be called precision resistors, and even higher precision resistors can achieve an accuracy of 0.01%. Generally, only thin film resistors and metal foil resistors can achieve high precision. The common series accuracy of resistors with a resistance value above 1Ω is above ±5%. The most common accuracy on electronic products is 5%, which does not fall within the range of precision resistors. Resistors with a resistance value below 1Ω generally achieve an accuracy within ±1%, which can be called precision resistors. Because for the same 1% error, the smaller the base of the resistance value, the smaller the absolute value of the resistance corresponding to 1%, and the higher the process and technical requirements. Even higher precision resistors can achieve an accuracy within ±0.5%, but the process and technical requirements are higher, resulting in higher resistor costs. Therefore, in high-precision application scenarios, to balance costs, other methods can be used to achieve the desired resistance value.

4. Power

Why do different processes have different rated power? The heat generated by the current flowing through the resistor is partly dissipated directly from the surface of the resistor, and partly transmitted to the substrate (ceramic tube) of the resistor, and then dissipated through the metal caps, copper leads, or even the printed circuit board (PCB) sleeved at both ends. The higher the thermal conductivity of the substrate material, the greater the rated power of the resistor. The substrate material for manufacturing ordinary (normal size) resistors is a kind of ceramic composed of alumina (Al2O3) and silica (SiO2); while the substrate material for manufacturing small size resistors is a special alumina ceramic, with alumina content as high as 80% to 93%. The higher the alumina content in the substrate material, the better the thermal conductivity, and the greater the rated power value of the resistor produced.

5. High Frequency

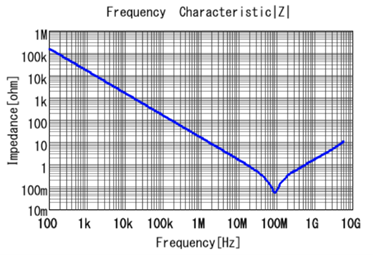

As graph 1 shown, the relationship between the absolute value of resistance impedance and frequency: at low frequencies, the impedance of the resistor is R. However, as the frequency increases and exceeds a certain value, the influence of parasitic capacitance becomes dominant, causing the resistance impedance to decrease. As the frequency continues to increase, due to the influence of parasitic inductance, the overall impedance increases, and the parasitic inductance represents an open circuit or infinite impedance at very high frequencies.

Different resistors have different structures, resulting in different parasitic inductance and parasitic capacitance. The parasitic inductance of non-wire wound resistors is usually smaller than that of wire wound resistors.

Graph 1. The relationship between the absolute value of resistance impedance and frequency

6. Noise

Different types of resistors have different noise characteristics. For example, metal film resistors have higher accuracy, better stability, lower noise, and smaller temperature coefficients compared to carbon film resistors.

Different Types of Resistors

Characteristics and Application Range of Different Types of Resistors

The manufacturing principles of resistors determines their characteristics. For instance, wire-wound resistors can provide relatively small resistance values (ranging from 0.01Ω to 100kΩ) due to limitations in wire specifications and possible turns, which prevent extremely large resistance values. As the winding length of wire is not infinite, wire-wound resistors cannot meet the demand for very large resistance values, requiring the use of resistors with other manufacturing processes. Because different types of resistors possess different characteristics, resistors are often applied to different purposes, as shown in Table 1.

|

Categories |

Characteristics |

Applications |

|

Wire wound resistor |

High accuracy, can be made into precision resistors with tolerances as low as 0.005%, and very small temperature coefficients; relatively large parasitic inductance, not suitable for high-frequency circuits |

High-power scenarios, high-precision applications, low-frequency scenarios |

|

Carbon film Resistors |

Low accuracy, not exceeding ±5%; low cost; poor ability to withstand high pulses, poor heat resistance |

Used in low-voltage circuits, situations where resistance accuracy requirements are not high |

|

Metal film resistor |

High accuracy, poor ability to withstand high pulses |

Used in low-voltage circuits, situations where high accuracy is required |

|

Metal oxide film resistor |

Poor ability to withstand high pulses, strong heat resistance |

Generates heat, situations where accuracy requirements are not high |

|

Glass glaze resistor/ Metal glaze resistors

|

High accuracy, high cost, strong ability to withstand high pulses, poor heat resistance |

Generates little heat, in high-voltage circuits

|

Table 1. Characteristics and Application Range of Different Types of Resistors

We will continue to study more details of each resistor, their materials and process.

Skip to content

Skip to content